When you walk past a construction site, you’ll likely notice the towering machinery that lifts materials skyward — these are construction cranes, vital for hoisting heavy loads.

The main categories of cranes used on construction sites include mobile cranes and fixed cranes. Each type is designed to perform in various environments and for specific lifting needs.

In this article, we will detail the different types of cranes commonly used in construction to help you identify and choose the suitable one for your project.

Overview of Construction Cranes

Cranes vary in form and function to meet the specific demands of different construction projects. Here’s a friendly breakdown to guide you through the primary types of cranes you’re likely to encounter:

- Mobile Cranes: They provide flexibility on-site with the ability to move on crawlers or tires. Featuring a boom arm for reach, these cranes are indispensable due to their mobility and relatively small footprint.

- Fixed Cranes: Fixed cranes are a type of crane that is permanently installed at a fixed location, as opposed to mobile cranes, which can move around a job site. The most recognizable type of fixed crane is Tower Crane. Recognizable by their height and lifting capacity, tower cranes are fixed to the ground or mounted on a structure. They are ideal for tall building projects due to their vertical and rotational reach.

Your construction project might need various equipment and machinery, but choosing the right crane is critical. Each component of the crane, from the boom to the bucket, serves a specific purpose.

Mobile Cranes

Mobile cranes are versatile lifting machines, capable of moving across various types of terrain with ease. Offering high degrees of mobility and flexibility, these cranes are essential for projects where the lifting requirements change frequently. This section will introduce different types of mobile cranes.

Truck-Mounted Cranes

Truck-mounted cranes, also known as truck cranes or boom trucks, provide a balance between lifting capabilities and mobility. Mounted on a truck chassis, these cranes are equipped with rubber tires that allow you to drive them on public roads. With outriggers that extend horizontally or vertically, they can stabilize the crane during operations. The boom extends directly from the truck and is often operated from a cab located near the boom. Truck cranes are smaller, so they are often used for lifting lighter loads.

Rough Terrain Cranes

Designed specifically for off-road and rough terrain applications with mud or snow, rough terrain cranes have four large rubber tires that are driven by a single engine. The engine powers both the undercarriage and the boom. These cranes have all-wheel driving capabilities, which provide greater traction and make them suitable for unsettled ground. They also have outriggers for stability during hoisting.

Rough terrain cranes are often used in confined areas. However, they are not road illegal. The crane operators need to drive them in a cab which swivels with the boom’s movement.

All-Terrain Cranes

As the name suggests, all-terrain cranes are built to handle a wide range of conditions. These cranes combine the roadability of truck-mounted cranes with the off-road proficiency of rough terrain cranes. With multi-axle tires and all-wheel drive systems, all-terrain cranes can navigate through both on and off-road sites. They typically offer quick setup and high-capacity lifting performance.

All-terrain cranes need to be assembled on-site cause they are also stabilized by outriggers.

Carry Deck Cranes

Carry deck cranes are the smallest, wheeled cranes with a rotating boom mounted on a flat deck or platform. They feature a deck area where loads can be picked up, carried short distances, and set down at the desired location. They are often used to carry objects from one area to another in construction sites. Their lift loads tend to be 4-10 tons, no more than 25 tons.

Crawler Cranes

Crawler cranes are unique in their use of crawler tracks rather than tires, which provide them with superior stability and mobility on soft ground like marsh. The absence of outriggers is counterbalanced by the tracks that distribute the crane’s weight over a greater area. Their booms can be substantial in length, allowing them to lift loads to significant heights, and these cranes are ideal for long-term projects on a single site because they must be disassembled for transport to a new location.

Floating Cranes

Floating crane is sometimes called crane vessel. When construction projects extend to the open water, floating cranes shine. Think of these as your water-based heavy lifters, often seen in the construction of bridges, ports, and offshore facilities. Their stability and strength, essential for nautical environments, allow you to tackle projects that defy typical grounded cranes with confidence.

Fixed Cranes

Tower Cranes

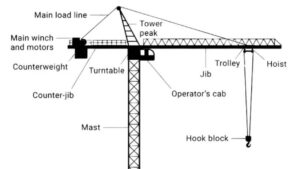

When you see a skyscraper being built, the chances are you’re looking at a tower crane in action. These cranes are the backbone of construction for tall buildings, combining a towering mast, a jib, and counterweights to provide the lifting power and stability needed for heavy and high-up tasks.

Self-Erecting Tower Cranes

Self-erecting tower cranes are your go-to option for projects with limited space and time. They’re designed to be assembled quickly—often using remote control—and without the need for additional cranes. Key features include a shorter mast and a folding jib, which make them easy to transport and ideal for jobs with lighter lifting requirements.

Luffing Tower Cranes

For work in congested areas, luffing tower cranes are indispensable. These cranes have a jib that can be raised and lowered to avoid neighboring structures. Crucially, their design minimizes the space needed for the crane’s operation, as the jib can be luffed up to a nearly vertical position, thus requiring less overhead room.

Hammerhead Crane

A hammerhead crane is a fixed tower crane with a long horizontal boom that extends outward from the top of the tower, resembling the shape of a hammer. The boom can rotate 360 degrees around the tower, providing a wide working radius.

Flat Top Tower Cranes

The characteristic feature of flat-top tower cranes is the absence of the “top hat” above the jib. This design enables them to work in tight spaces, especially where multiple cranes might overlap. With their flat tops, these cranes facilitate easier and safer assembly and disassembly as well as operation beneath overhead obstacles, like other cranes or power lines.

Specialized Fixed Cranes

Gantry Cranes

Your gantry crane—characterized by its gantry structure—is designed for tasks that call for heavy lifting across a fixed route. A typical gantry crane comprises a hoist and is mounted on a trolley, which moves across a rail system known as the runway. It’s particularly useful in shipyards and steel fabrications, easily managing heavy materials within its set confines.

Bridge/Overhead Cranes

Also known as bridge cranes, overhead cranes consist of parallel runways with a traveling bridge spanning the gap. Essential for indoor settings like factories, these cranes move objects with a hoist or trolley, contributing greatly to efficiency. You’ll appreciate its high level of precision and safety during intensive material handling tasks.

IHURMO offers a wide range of tower canes for any work site and invites you to reach out with any inquiries. If you have any questions, please consult with our specialists.

Frequently Asked Questions

How are tower cranes and mobile cranes distinct from each other?

Tower cranes are fixed structures with a tall mast and jib, best suited for height and heavy lifts within a concentrated area. Mobile cranes, on the other hand, are movable and are used for a range of lifting tasks that require flexibility and mobility across the construction site.

What are the names of the largest cranes utilized in construction projects?

The largest cranes in construction include the Liebherr LR 13000 and the Manitowoc 31000. These cranes are designed for heavy lifting and are capable of lifting thousands of tons with precision.

Can you list the uses for different types of cranes in construction?

Certainly. Mobile cranes are versatile and used for lifting materials and equipment. Tower cranes are ideal for constructing tall buildings. Rough terrain cranes are used where the ground is uneven. Crawler cranes move on tracks and are suitable for soft or rugged terrain, whereas bulk-handling cranes are used for moving vast volumes of materials such as coal or minerals.

What components make up a typical tower crane?

A typical tower crane consists of a base, a mast, a jib, and a hook. The tower stands tall with the jib extending horizontally to lift materials to and from heights.

How does a self-erecting crane operate compared to traditional cranes?

Self-erecting cranes are smaller than traditional cranes and are operated by remote control without the need for assembly by another crane. They’re quick to set up, efficient for short-term projects or confined spaces, and are particularly useful where frequent crane relocation is required.