Mast climbers work as innovative vertical access solutions. As a leading manufacturer in the field, IHURMO has been at the forefront of mast climber technology, providing cutting-edge solutions for construction projects worldwide. This article explores the fundamental aspects of mast climbers and their benefits.

What is Mast Climber?

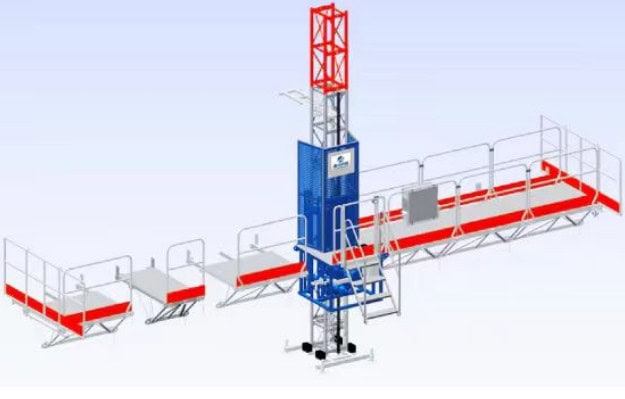

A mast climber also called a mast climbing work platform (MCWP), is a safe and efficient way for workers to reach heights. Commonly used in construction, these platforms provide access to building facades, high walls, and other elevated areas.

Mast climbers are suitable for both short-term projects and long-term use. They can be fixed to a building or used as a mobile unit.

Unlike traditional scaffolding or ladders, mast climbers offer a more flexible and adaptable solution. The platforms are attached to vertical masts and can be easily raised or lowered to the desired height using a powered mechanism. This makes them a more adaptable solution, allowing workers to quickly and easily reach even the most difficult spots.

What are the Components of a Mast Climber?

A mast climber consists of several key components. Here are the main components of a typical mast climber:

Platform Components

- Work Platform: This is the main deck where workers stand and materials are placed. IHURMO’s mast climbers are typically made of aluminum sheets for durability and lightweight properties.

- Surrounding Railings: These provide essential fall protection for workers on the platform, increasing overall safety.

Mast Components

- Mast Sections: Here at IHURMO, we manufacture these sections from precision-welded,hot-dip galvanized steel, and allowing them to be assembled to reach the required height.

- Cable Holder: This component manages and organizes the power cables as the platform moves up and down.

- Cable Guide: This ensures that the cables follow a proper path during platform movement.

- Snagging Device: This prevents cables from getting caught or tangled during operation.

- Cable Drum: It stores and releases the necessary length of cable as the platform moves.

Base and Mobility

- Chassis: Mast climbers can be equipped with either a wheel chassis or a mini-chassis for mobility.

- Outriggers: Swiveling telescopic outriggers provide stability and allow the machine to stand without anchoring.

Control System

- Control Panel: This allows operators to control the platform’s movement and other functions.

When to Use Mast Climbers?

Commercial Projects

Mast climbers are ideal for new construction projects, particularly when working on building facades.

High-rise construction projects use mast climbers to carry heavy materials to elevated floors, reducing the need for cranes.

Mast climbers are also used in the renovation of a historic building. Mast climbers enabled workers to repair facade details without disrupting ongoing business activities.

Furthermore, they are useful for installing and maintaining large signs on building exteriors.

Residential Use

For residential purposes, mast climbers are particularly useful for tasks like painting, window cleaning, and minor repairs on multi-story homes. They offer a safer alternative to traditional ladders and scaffolding.

What are the Benefits of Using Mast Climbers?

Using mast climbers in construction has many benefits. These include improved worker productivity, better safety measures, and increased versatility and accessibility on job sites.

Enhanced Productivity

Mast climbers are especially suitable for medium to high-rise construction projects.

With mast climbers, you can reach different heights quickly, reducing downtime. This makes tasks like repairs, restoration, and new construction faster than using scaffolding.

The larger platform allows you to move materials up and down the building more efficiently, saving you time and energy.

Additionally, mast climbers become increasingly cost-effective as building height increases; generally speaking:

- At 6 floors, a mast climber can save around 13% in costs compared to traditional scaffolding

- At 12 floors, the savings jump to 60%

- At 18 floors, the savings increase to 70%

- For buildings over 18 floors, savings can reach up to 80%

Improved Safety

Mast climbers are designed with safety in mind. Unlike traditional scaffolding, mast climbers have fewer loose parts, making the setup firmer.

Safety barriers and railings add additional protection for your workers while working at heights. The risk of falling is minimized, which can lead to fewer job site injuries.

Emergency stop mechanisms and controlled descent features allow you to address potential safety issues quickly, ensuring a safer work environment.

Versatility and Accessibility

The easy setup and breakdown of mast climbers mean they can be relocated and adjusted quickly as your project evolves.

Mast climbers are highly versatile and adaptable to different projects.

IHURMO can customize different mast climbers to fit various facades and structures, making them suitable for both small and large-scale projects. You can contact us to adjust the height of the platform to match your specific needs.

What is the Capacity of a Mast Climber?

The load capacities of IHURMO’s mast climbing work platforms vary depending on the specific model, which offers load capacities ranging from 1 ton to 4 tons, depending on whether it’s a single or twin mast configuration.

The SCP230 model has a load capacity of 1000-4200kg, while the SCP200-12D model has a lower load capacity.

Here are the parameters:

| Team | SCP230/9D | SCP200/12D | ||

| Single mast | Twin mast | Single mast | Twin mast | |

| Max length(m) | 10.5 | 24 | 13.5 | 30 |

| Standard with(m) | 1.5 | 1.5 | 1.5 | 1.5 |

| Max. with(m) | 2.7 | 2.7 | 2.7 | 2.7 |

| Max. mast height free-standing(m) (chassis) | 10 | 10 | 10 | 10 |

| Motor power(kW) | 2×2.2 | 2×2×2.2 | 2×3 | 2×2×3 |

| Distance between tie-in(m) | 3-6 | 3-6 | 3-9 | 3-9 |

| PLC | Schneider | Schneider | Schneider | Schneider |

| Transducer | Overload, force, torque, and angle | |||

How to Choose From Mast Climbers, Suspended Platforms and Scaffolding?

Mast climbers offer various advantages when compared to traditional scaffolding and suspended platforms. They are typically more adaptable and can lead to cost savings, especially at higher elevations.

Here’s a chart comparing mast climbers, suspended platforms, and traditional scaffolding :

| Aspect | Mast Climbers | Suspended Platforms | Traditional Scaffolding |

| Height of Work | Efficient for medium to high-rise buildings | Ideal for very tall structures | Cost-effective for lower heights |

| Fall Protection | Built-in guardrail systems | Require additional fall arrest systems | Needs proper guardrails and fall protection measures |

| Weather Resistance | Can withstand powerful winds, allowing work in challenging conditions | It may have limitations in windy conditions | Stability can be affected by severe weather |

Frequently Asked Questions

What are the safety standards for operating mast climbers?

Mast climbers are covered under OSHA regulation 29 CFR 1926 Subpart L – Scaffolds. The ANSI A92.9-2011 standard provides specific guidelines for Mast-Climbing Work Platforms.

What is IPAF?

IPAF (International Powered Access Federation) is a global non-profit organization that promotes the safe use of powered access equipment through comprehensive training programs and certification.

Its widely recognized PAL Card (Powered Access License) is issued to operators who successfully complete IPAF training, covering various types of equipment such as MEWPs and mast climbers, and is valid for five years.

What type of training is required to operate a mast climber safely?

Operators must receive training that should cover topics like safe operation, hazard awareness, daily inspections, safety systems, load charts, and material handling.

Training must be conducted by qualified instructors who have completed an OSHA 500 course and at least one mast climber manufacturer certification or relevant work experience.

How does the cost of a mast climber compare to other access solutions?

While the mast climbers may have a higher initial cost compared to traditional scaffolding, they can be more cost-effective in the long run. Their efficiency, reduced labor requirements, and improved safety can lead to overall savings on construction work.

What are the differences between MEWP and MCWP in the construction industry?

MEWPs (Mobile Elevating Work Platforms) are mobile, versatile platforms like scissor lifts and boom lifts, designed for short-term tasks at various heights with quick setup, while MCWPs (Mast Climbing Work Platforms) are fixed-mast structures used for longer-duration work on tall buildings, offering higher load capacity and reaching greater heights.

The key distinction lies in their mobility, with MEWPs being easily relocated around a job site. In contrast, MCWPs require more extensive installation but excel in providing stable, high-capacity platforms for extended work on building facades.