Cranes are indispensable machines in various industries, from construction to manufacturing. These powerful devices are designed to lift, lower, and move heavy loads with precision and efficiency, making them essential for tasks that require strength and accuracy.

The efficiency and safety of a crane depend heavily on its components, each of which plays a critical role in its operation.

Understanding the basic parts of a crane is essential for operators, engineers, and anyone involved in crane maintenance or safety.

Follow Ihurmo to know the parts’ functions and how they work together to ensure smooth and safe operations.

Crane Base

The base serves as the crane’s structural anchor, designed to transfer all operational forces (weight, torque, wind) into the ground. Its complexity varies by crane type:

- Materials & Construction:

- Mobile Cranes: Use heavy-duty steel frames integrated with the carrier vehicle.

- Tower Cranes: Require reinforced concrete foundations, sometimes with pilings driven 30–50 feet deep for skyscraper projects.

- Crawler Cranes: Employ a wide, low-profile tracked base to distribute weight evenly on soft terrain.

- Key Engineering Principles:

- Stability Triangle: The crane must remain within a geometric zone where the center of gravity (combining crane, load, and counterweights) projects within the support base.

- Terrain Adaptation: Dynamic bases use hydraulic leveling legs or grout mats on uneven ground.

- Anchoring: Massive anchor bolts or ballast blocks secure the base against overturning moments, especially in high-wind conditions.

Outriggers

Outriggers are deployable supports that widen the crane’s “footprint”.

- Types & Mechanics:

- Hydraulic Outriggers: Common in mobile cranes; extend vertically and horizontally via pressurized fluid systems. Some include “float” modes for uneven surfaces.

- Box/Folding Outriggers: Compact designs for confined spaces.

- StabIlizing Leg: It extends outward from the base of the crane to distribute the weight and forces exerted during operation, preventing tipping and enhancing the tower crane’s overall stability.

- Critical Functions:

- Load Distribution: A 100-ton mobile crane might exert 40 psi on outrigger pads; without them, pressure could exceed 200 psi, risking ground failure.

- Moment Resistance: Outriggers counter the rotational force generated by the boom. For a 10-ton load at a 50-foot radius, the moment is 500 ton-feet—outriggers must offset this through their spread.

Counterweights

Counterweights balance the load on the opposite side. These heavy blocks offset the weight of the load and boom, preventing the crane from tipping forward.

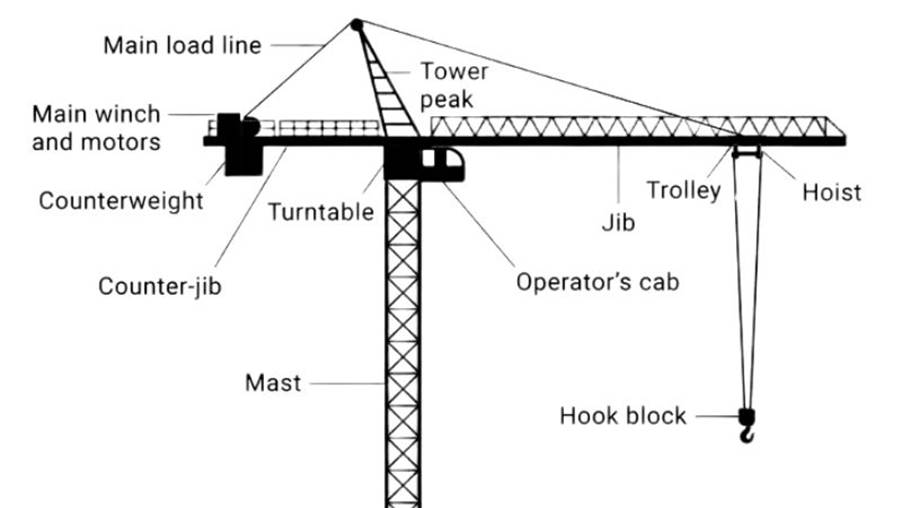

Trolley

The trolley is a motorized cart that runs horizontally along the crane’s jib. Its purpose is to position the hook and lifting cables precisely, allowing workers to transport loads efficiently across the site.

Key Features:

- Movement: The trolley moves back and forth along the jib via remote or cab controls.

- Load Management: It ensures smooth horizontal transport of materials, minimizing sway.

- Safety: Modern trolleys include braking systems and overload sensors.

- Versatility: Adjustable to handle varying weights and distances.

Mast

The mast is your crane’s vertical support structure. It provides the height needed to lift objects and supports the boom system above.

In tower cranes, this vertical section can reach a heights and is built in sections as the structure grows taller.

The tower must withstand not just the weight of loads but also side forces from wind and movement, so it’s designed with heavy steel components and reinforcements to handle tremendous forces while maintaining stability.

Tower Peak

The tower peak of a tower crane refers to the uppermost structural section of the crane’s vertical mast, which serves as the critical junction connecting the static tower to the rotating upper structure.

It anchors the jib (horizontal lifting arm) and counter jib (counterweight arm), distributing forces to maintain balance during lifting operations.

Key Features and Functions:

- Structural Hub: The tower peak is the apex of the crane’s mast, typically housing the slewing mechanism (a large rotating bearing or gear). This allows the crane’s jib (working arm) and counter-jib to rotate 360 degrees, enabling precise load placement.

- Support for Upper Components:It anchors the jib and counter jib, distributing forces to maintain balance during lifting operations.

Operator’s Cab and Controls

The operator’s cab is where all the action happens.

Inside the cab, you’ll find various control systems the crane operator use everyday that include:

- Joysticks: For precise movement of the crane components

- Buttons and switches: To activate different functions

- Digital displays: Showing load weight, radius, and height information

- Computer systems: In newer models for enhanced precision

The control panel allows you to manage all crane movements including lifting, lowering, and rotating.

Hoist

The hoist on a tower crane is the mechanical system responsible for lifting, lowering, and controlling loads vertically. It is a core component of the crane’s lifting operations.

Key Components of the Hoist System

Hoist Motor

A powerful electric or hydraulic motor drives the hoist mechanism. Modern cranes often use variable-frequency drives (VFDs) for smooth acceleration and deceleration, reducing load swing.

Wire Rope

High-strength steel cables (wire ropes) connect the drum to the hook block. These ropes are engineered to handle extreme tensile forces and which need regularly inspected for wear or damage.

Hook Block

A pulley system with a hook (or shackle) that attaches to the load. Multiple sheaves (pulleys) in the block create mechanical advantage, reducing the force needed to lift heavy weights.

Boom

The boom is the primary lifting arm of a crane, designed to hoist and maneuver heavy loads. It serves as the structural backbone, enabling vertical and horizontal movement of materials.

Types of Booms

Lattice Boom

Constructed from a framework of steel trusses, forming a lightweight yet strong lattice structure. Common in crawler and tower cranes.

Modular sections allow customization in length and are ideal for heavy lifts with long reach.

Telescopic Boom

Comprises nested steel sections that extend hydraulically which used in mobile and rough-terrain cranes for rapid setup and compact transport. They have adjustable length without disassembly.

Hammerhead Boom

A horizontal, fixed-length arm on tower cranes, often with a trolley system for lateral load movement.

Articulating Boom

Features hinged sections for precise, flexible positioning, common in material handlers and maritime cranes.

The boom’s length determines the crane’s maximum reach, while its design affects load capacity. The longer the boom extends, the less weight it can safely lift.

Cooperate With IHURMO

Ihurmo focus on creating custom-designed hoists and tower cranes that address the specific demands of your project site.

Our machinery is certified to CE, ISO, and ANSI standards, and the best part? High quality doesn’t have to mean high costs.

By leveraging streamlined and factory-direct pricing, we provide top-tier equipment at competitive rates. Get in touch today—let’s collaborate to build smarter solutions.

Frequently Asked Questions

How to choose a crane for my construction site?

To choose a crane for your job site, consider factors such as load capacity, height and reach requirements, site conditions, and the type of work being performed.

Additionally, evaluate your budget and ensure that you have trained operators familiar with the crane type you select.

What are the types of crane?

The main types of cranes include mobile cranes, tower cranes, overhead cranes, jib cranes, gantry cranes, floating cranes, rough terrain cranes, pillar cranes, and telescopic cranes, each designed for specific lifting tasks and environments.

What are the main parts of the crane?

The main parts of a crane include the boom, hoist, trolley, hook, counterweight, base, and operator’s cab, each playing a crucial role in lifting and moving loads.