Tower cranes are engineered to rise upwards in sync with a building’s vertical growth. As construction progress, specialized climbing systems, such as hydraulic jacks or climbers, are used to incrementally elevate the crane’s towering mast to higher floors. This upward progression requires meticulous coordination and strict safety protocols to enable a smooth and controlled ascent.

The sight of a tower crane perched atop a skyscraper under construction has become an iconic symbol of modern urban landscapes. These massive crane structures play a crucial role in the construction of high-rise buildings, enabling the lifting and placement of heavy materials and equipment at dizzying heights.

Cranes are assembled atop skyscrapers using methods such as the external climbing method, where the crane expands upward along the building’s exterior, or the internal climbing method, where the crane ascends from within the building. Heavy-lift helicopters may also transport crane parts to the site when necessary. Read this article, and we will decode how tower cranes get on top of buildings.

Crane Operation and Safety Considerations

Getting cranes on top of a building is a high-risk endeavor that requires stringent safety measures and protocols. A tower crane always has an overload system, which includes Load Moment Indicators, Rated Capacity Indicators, and Anemometers. These are crucial for safe and efficient crane operations:

Load Limits and Capacity Indicators

Cranes have specific load limits and rated capacities based on factors such as boom length, radius, and wind conditions. To prevent overloading and potential accidents, cranes are equipped with:

- Load Moment Indicators (LMI): Electronic systems that continuously monitor the crane’s load and boom configuration, providing real-time feedback to the operator.

- Rated Capacity Indicators (RCI): Visual displays or warning systems that alert the operator when the crane approaches its rated capacity.

- Maximum Safe Working Load Cutout: This device cuts off crane movements like hoisting or trolleying out that would cause an overload condition exceeding the crane’s rated capacity. It works in tandem with the LMI system.

Weather Monitoring Systems

Wind and weather conditions can significantly impact crane operations and stability. Cranes on top of the buildings are typically equipped with:

- Anemometers: Devices that measure wind speed and direction, enabling operators to adjust operations or halt work during high winds.

Crane Climbing Techniques

As these tall buildings grow taller, cranes must be able to elevate or increase their height to maintain efficient operations. Several techniques are employed to achieve this.

Using a Second Crane

This method requires use of another crane to achieve the goal. Although it is possible, using a second crane is not often done on construction sites. Because it is very dangerous and only skilled operators can carry two cranes at the same time.

External Climbing Method

The external crane method is used when the tower crane is located outside the structure being built. It involves the use of a climbing frame or climbing cage that surrounds the crane tower. Some people consider it the most effective way to get cranes to reach the top because it minimizes downtime. The key steps in external climbing are:

- Base Building: Construct a base of the crane with concrete and utilize a mobile crane to help the tower crane erected on the base. Remember, the crane base needs to be very stable.

- Climbing Frame Assembly: A climbing frame or cage is assembled around the crane tower at the desired elevation where the tower needs to be extended. The climbing frame is a structural steel frame that surrounds the crane tower and includes integrated hydraulic jacking systems.

- Hydraulic Jacking: The climbing frame is equipped with hydraulic jacks that are strategically positioned around the crane tower. These jacks are synchronized to lift the entire crane tower upwards in incremental stages, typically ranging from 20 to 30 feet (6 to 9 meters) at a time.

- Mast Section Insertion: As the crane tower is lifted by the hydraulic jacks, new mast sections are inserted beneath the raised tower. These mast sections are pre-assembled on the ground and then lifted into position using the crane’s hoisting mechanism or an auxiliary crane.

- Bolting and Securing: Once the new tower sections are in place, workers secure them to the existing tower using high-strength bolts and connections. This process ensures the structural integrity and stability of the extended tower. Climbing Frame Relocation: Once the new tower sections are bolted and secured, the climbing frame is dismantled and reassembled at the higher elevation. This process is repeated as the building construction progresses, allowing the crane to climb upwards along with the structure.

- Anchoring Ties: As the crane tower grows taller, it is typically tied into the building’s structural elements using steel collars or bracing systems. These tie-ins provide extra support and stability to the crane tower, preventing it from swaying or toppling over due to wind loads or other forces.

Internal Climbing Method

The internal climbing method is employed when the crane tower is erected inside the center of the building itself. As new floors are added, the crane climbs up using the building’s structural elements for support. The steps involved are:

- The crane tower is initially erected through or alongside the building’s core.

- As new floors are constructed, the crane’s vertical movement is guided by climbing rails or guides attached to the building’s core.

- A hydraulic cylinder integrated into the crane’s tower lifts the crane up in increments to the next floor level. After that, the workers can slide the steel beams to create a new footing.

- The process is repeated as the building rises higher.

Heavy Lift Helicopter / Skycrane

In certain situations, especially for construction in remote or inaccessible areas, heavy lift helicopters are used for aerial crane operations. These helicopters can lift and place heavy loads with precision using long sling lines. However, this method must be done piece by piece and can be quite expensive, so it is not highly recommended when getting cranes reach the top. Key advantages of heavy lift helicopters include:

- Ability to access remote sites without the need for roads or ground infrastructure

- Rapid deployment and relocation of equipment and materials

- Precise placement of loads in confined or congested areas

- Reduced environmental impact compared to traditional ground-based cranes

Heavy lift helicopters are commonly used in utility infrastructure projects, remote area construction, aerospace operations, firefighting, and disaster relief efforts where traditional cranes cannot be easily deployed.

All three crane climbing techniques have specific applications based on project requirements, site conditions, and logistical constraints. Crane Disassembly and Removal

Once a skyscraper construction project is completed, the process of crane disassembly and removal must be carefully executed. This phase is just as critical as the installation and operation stages, requiring meticulous planning and adherence to safety protocols.

Reverse Installation Process

In many cases, the crane disassembly process follows the reverse order of the installation and assembly procedures:

- Electrical and Control Systems Disconnection: The crane’s electrical systems, control panels, and safety devices are safely disconnected and removed.

- Counterweight Removal: Counterweights are carefully unloaded and transported away from the site.

- Boom/Jib Disassembly: The horizontal boom or jib is detached and lowered to the ground or a lower level of the building.

- Tower/Mast Disassembly: The tower or mast sections are systematically disassembled and lowered, often using a mobile crane or the crane itself in a self-dismantling process.

- Base Removal: The crane’s base is disassembled, and the site is cleared and prepared for additional construction activities or restoration.

Crane Segment Dismantling

For cranes with modular climbing sections or vertebrae, the disassembly process may involve:

- Controlled Retraction: The crane’s height is gradually reduced by retracting or removing the climbing sections one by one.

- Segment Lowering: Individual crane segments are detached and lowered to the ground or a lower level using mobile cranes or heavy-lift helicopters.

Site Clean-up and Restoration

After the crane has been completely disassembled and removed, the construction site undergoes a thorough clean-up and restoration process:

- Debris Removal: Any remaining debris, materials, or equipment related to the crane operations are removed from the site.

- Surface Restoration: Concrete slabs, anchor points, or other surfaces impacted by the crane installation are repaired or restored to their original condition.

- Site Inspection: Final inspections are conducted to ensure the site is safe and ready for subsequent construction phases or occupancy.

Key Considerations:

- Reverse Logistics Planning: Developing detailed plans for the transportation and disposal of disassembled crane components.

- Safety Protocols: Implementing strict safety measures, such as exclusion zones, fall protection, and crane inspection protocols, during the disassembly process.

- Environmental Compliance: Ensuring the proper disposal of any hazardous materials or waste generated during the crane removal process.

Frequently Asked Questions

What is the purpose of the cranes on top of skyscrapers?

The primary purpose of cranes at such heights is to lift and place construction materials, facilitating efficient high-rise construction and minimizing the need for ground-based lifting equipment, which may be less feasible or more time-consuming for tall structures.

How do operators ascend to the cab of a high-rise tower crane?

Operators typically access the crane cab via a combination of elevators and ladders. The final ascent often involves climbing a ladder within the crane’s mast to access the cab, where they spend their workday.

Are there restroom facilities available for crane operators working at great heights?

Some high-rise tower cranes are equipped with a small, basic restroom facility within the operator’s cab for convenience due to the impracticality of descending frequently throughout the workday. But this is not common.

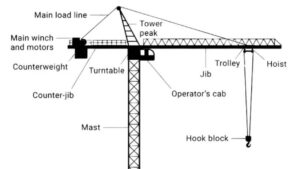

What are the main components of a tower crane?

The main components of a tower crane include the base, the mast that gives the crane its height, the slewing unit for rotation, the jib for holding counterweights, the operator’s cab, and the hook used for lifting loads.