A boom and jib isn’t academic in construction — it directly affects safety, productivity, and cost.

Ihurmo professionals spent years on construction sites. Below is a practical, hands-on comparison to help you choose the right equipment for lifting heavy loads.

Key Takeaways

- A boom is the heavy-lifting backbone; a jib is the reach-and-finesse accessory.

- Choose booms when you need high load capacity; choose jibs to overcome site constraints or for precision placement.

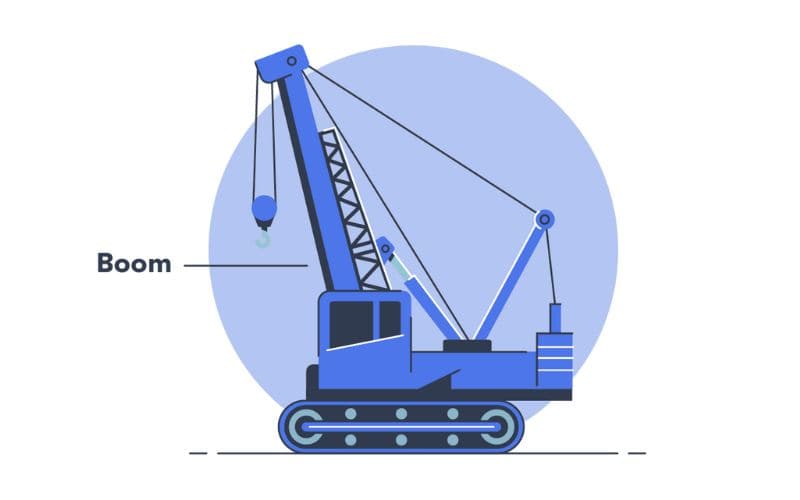

What is a Boom

A boom is the primary structural arm of many mobile cranes and telescopic cranes.

It’s typically a long, rigid member that extends out from the machine’s superstructure and carries the hoist line and hook.

Booms can be fixed lattice structures or telescopic sections that extend and retract hydraulically.

Telescopic booms use hydraulic sections for quick extension; lattice booms are lighter per length and offer better strength-to-weight for very high lifts.

Furthermore, articulating boom has multiple hinged sections for precise placement in constrained spaces which commonly on truck-mounted cranes and aerial work platforms.

They are designed for variable outreach and high load capacity.

Booms in Action

- Erecting steel frames: Use a lattice or telescopic boom with adequate load capacity; a boom gives the hoist steady vertical lift for heavy loads.

- Concrete panel placement: Telescopic booms are fast and reduce setup; operators frequently adjust outreach to control panel placement.

- Heavy lifts on uneven ground: Lattice booms combined with proper counterweight and ground preparation provide stability.

What is a Jib?

A jib is a secondary arm attached to the main boom or crane tower. It typically increases reach and fine placement ability without the weight and complexity of a longer boom.

On tower cranes, the jib forms the horizontal working arm; on mobile cranes it may be an auxiliary extension or a jib attached to the boom tip to reach over obstacles.

What are Different Types of Configurations of Jibs?

- Fixed jib: Simple extension welded or bolted to a boom or tower; low complexity.

- Swing-away jib: Hinged at the boom tip and can be raised/lowered or rotated to clear obstructions.

- Luffing jib (on tower cranes): Moves up and down to vary radius without large swing area — ideal for dense construction sites.

- Extension/jib insert: Telescopic-like sections or lattice adapters to increase outreach temporarily.

Key Features of a Jib

- Increased outreach: It let you reach beyond the boom’s maximum or place loads in tight spots.

- Fine placement: Offers more precise load positioning for hoist work.

- Lightweight extension: Adds reach without the full weight penalty of a longer boom.

- Compatibility: Many jibs are modular and can be fitted to different cranes or tower crane models.

- Common on tower crane types such as hammerhead and luffing-jib tower cranes.

Jibs in Action

- Work above and around obstacles: A swing-away jib helps place hoist loads behind parapets or inside constrained zones.

- Tower crane placements: A hammerhead or luffing jib gives precise horizontal axis movement for placing materials across floors.

- Final fit and fine placement: Jibs give operators the last few meters of control to slot components into place without repositioning the base crane.

Why the Difference Matters?

Differences really matter. Cause when you select a crane, you should consider the load capacity and safety.

Booms carry heavier loads at shorter radius; however, adding outreach will reduce the load capacity.

When it comes to the construction site,on crowded one, a luffing jib or swing-away jib can be better than trying to extend a boom.

Comparison Chart of Jib and Boom

| Feature | Boom | Jib |

| Primary purpose | Main lifting arm for heavy loads | Extension for added reach/fine placement |

| Typical capacity | High (varies with radius) | Lower than main boom at same radius |

| Common forms | Telescopic, lattice, articulating | Fixed, swing-away, luffing, telescopic insert |

| Best for | Heavy lifts, structural placement | Reaching over obstacles, fine adjustments |

| Operator considerations | Cab control, boom angle/length affects capacity | Changes load charts — operator must recalculate radius |

| Ideal use case | Crane for your project when heavy loads needed | Construction sites with obstructions or tight radii |

How to Select a Crane?

Differenct types of jib crane:

- Tower crane jibs (hammerhead, luffing, topless): Choose based on site footprint and required radius.

- Mobile crane jibs (fixed, swing-away, telescopic jib): Select for transportability and quick setup.

- Derrick/jib combinations for specialized hoist tasks.

Factors to consider when selecting a jib crane:

- Load capacity needed at the maximum radius.

- Maximum and working radii.

- Site constraints: swing area, nearby structures, and underground utilities.

- Operator access and visibility for hoist operations.

- Attachment compatibility with your existing crane fleet or provider.

- Frequency of use and whether a modular jib (removable) makes sense for your workflow.

- Define the maximum load and lift radius.

- Check site access and height restrictions.

- Decide whether you need telescopic speed or lattice strength.

- Evaluate whether a jib will improve reach/fine placement without overcomplicating rigging.

If your project needs a reliable supplier with multiple crane configurations, consider IHURMO.

IHURMO supplies tower cranes, construction hoists, suspended platforms, and related lifting equipment.

For many contractors and rental operations, IHURMO can supply a tower crane configurations tailored to your site.

Browse their product lines at IHURMO to match models to your load capacity and outreach needs.

Frequently Asked Questions

What is the primary function of a crane boom?

A crane boom serves as the main lifting structure, providing the necessary height and support to lift and move loads efficiently.

How does a jib extend a crane’s functionality?

A jib extends the reach of a crane, making it possible to access areas beyond the standard capacity of the boom.

What are the different types of crane booms?

Crane booms can be telescopic, lattice, or articulating.

In what scenarios are jibs particularly useful?

Jibs are ideal for tasks requiring precision movement in confined or challenging spaces, such as manufacturing or storage facilities.

What considerations are important when using a crane jib?

When using a crane jib, it is essential to account for reduced load capacity due to leverage.

Why is understanding the distinction between a jib and a boom important?

Recognizing the differences between a jib and a boom allows for the selection of the correct configuration for specific tasks, improving crane efficiency and safety.